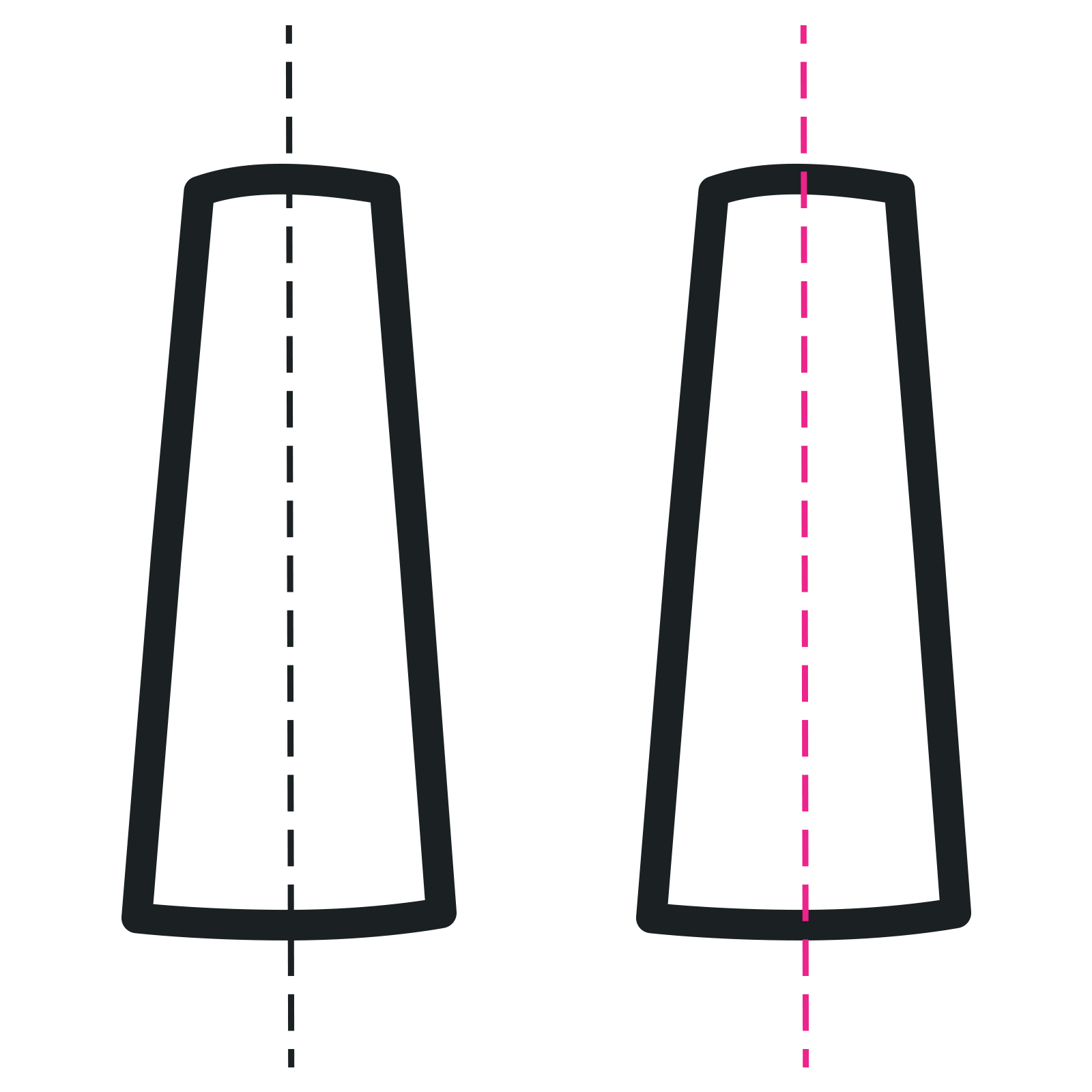

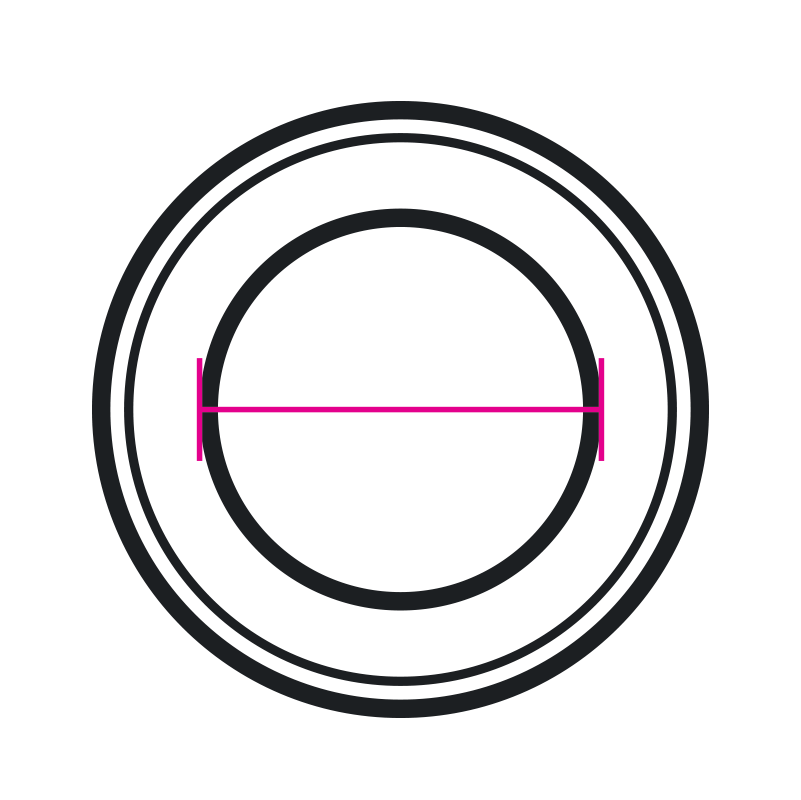

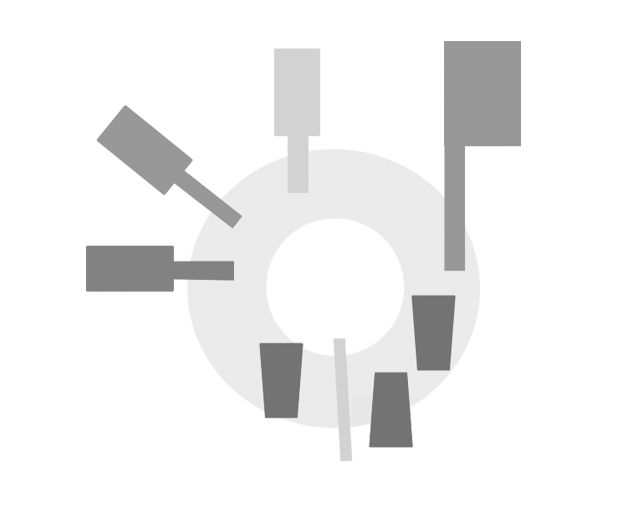

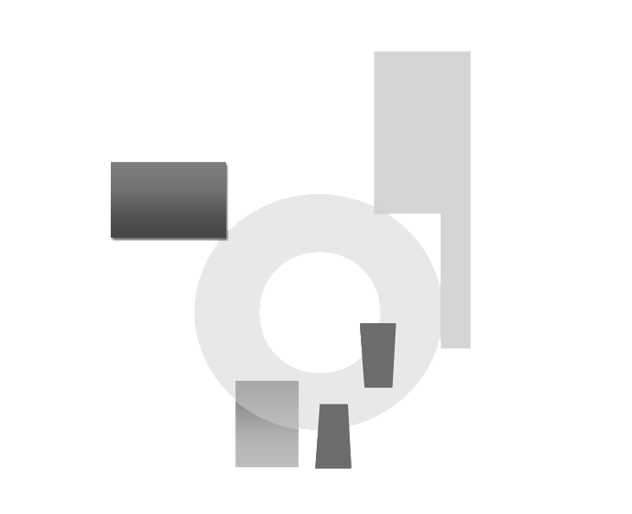

Among the visual inspection machines in the catalog, VIM has machines to detect dimensional defects on parts in a wide variety of shapes and materials. These visual inspection machines for dimensional controls measure diameters, concentricity, roundness, axis distances, flatness and angles, in order to scrap the parts that do not comply with the requirements communicated by the customer. The control of the orientation and / or the perpendicularity of the pieces is also part of the dimensional checks.

Parts dimension

Single-glass visual inspection machine, "transparent glass-optical-table". Automatic feeder with integrated vibrating cup.

CONTINUE

Parts dimension

Single-glass visual inspection machine, "transparent glass-optical-table". Automatic feeder with 200 liters of autonomy.

CONTINUE

Parts dimension

Double table visual inspection machine, "glass-optical-table". Automatic feeder with great autonomy (200 liters of capacity).

CONTINUE